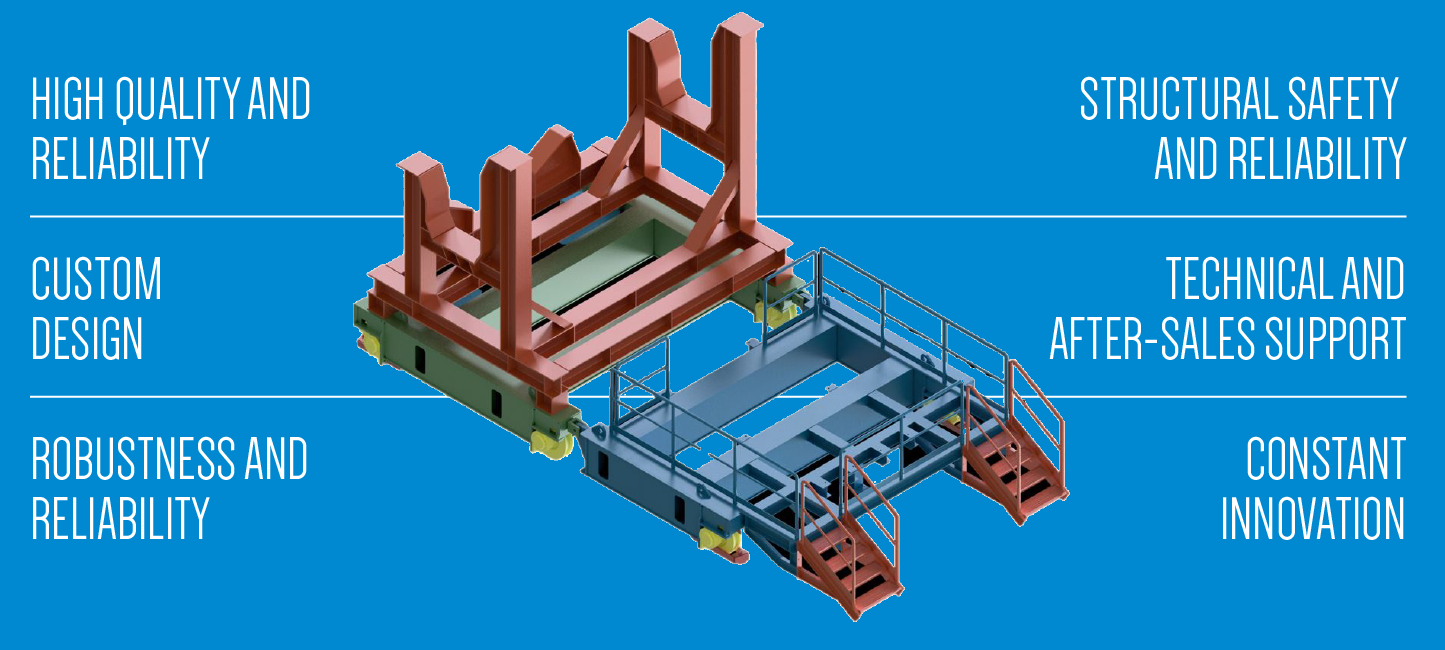

Where high complexity and maximum reliability meet

Our capacity to manufacture critical structural steel components is based on a modern and complete infrastructure, equipped with advanced machinery that allows the machining of complex and large dimension parts. We have a strict process control, and a staff of engineers specialized in design and simulation. All the same, our certified inspectors supervise every process, from the entry of raw material to the machining, forming, welding and painting, guaranteeing maximum reliability and quality in every part we manufacture.

Whether using our engineering or the drawings and technical files provided by the customers, we ensure that each critical structure steel component meets the highest industry standards.

We guarantee that our components comply with safety regulations, providing peace of mind and safety in their use.

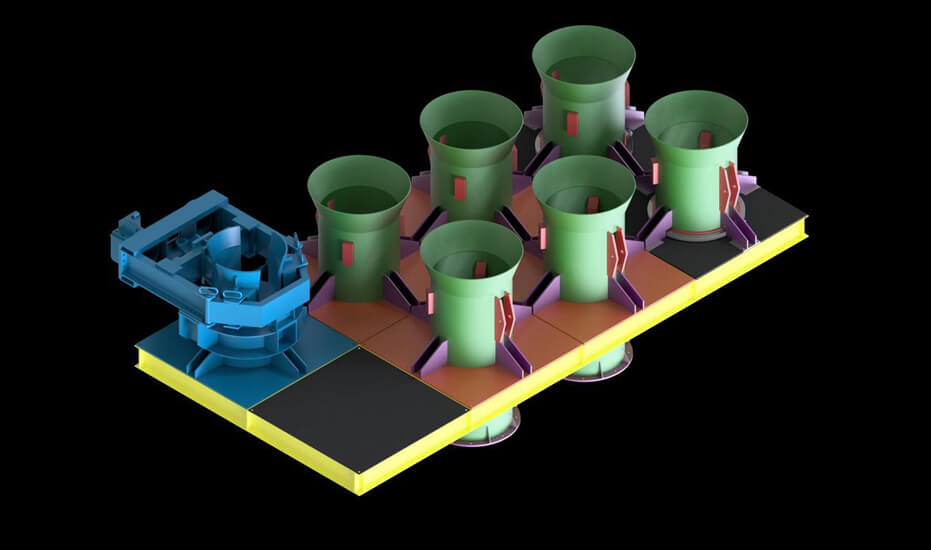

Among the main structural components that our clients trust us with, we have:

Our engineers work closely with customers to design components that perfectly match their specific needs.

Comprehensive and precision manufacturing, all in ITALMECAN

Development of initial ideas, viability studies, structural design, technical specifications and production of accurate designs and detailed drawings, for structural component manufacturing and assembly.

Documentation and development of the necessary structural calculation to guarantee the integrity and safety of the component, using design software and advanced simulation to carry out finite element analysis and assess structural behavior under different conditions.

Design of drawings that reflect the final state of the structure after its construction, including modifications.

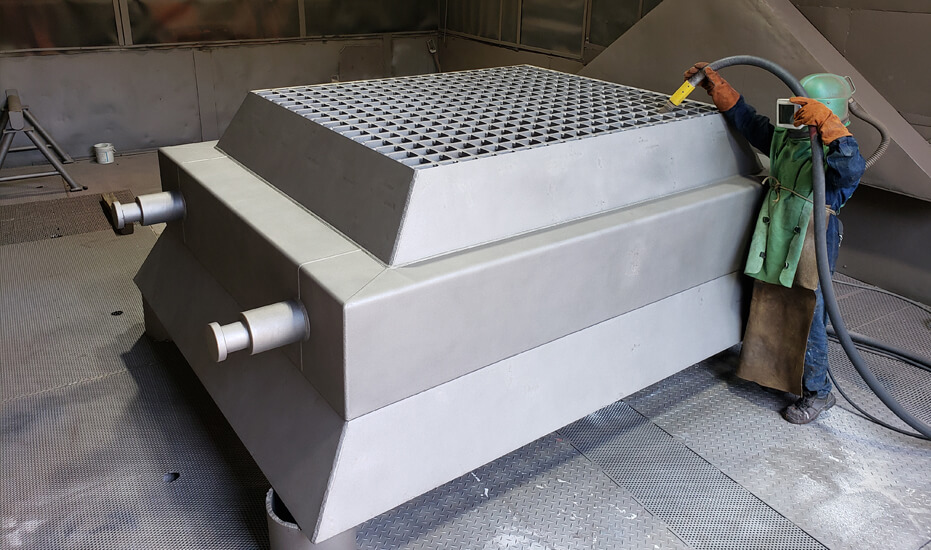

Cleaning and preparation of metallic surfaces through blasting and application of protective coatings, using AIRLESS painting system to ensure uniform and lasting cover.

Reduction of residual stress in structural components through thermal treatment and the use of controlled vibrations to improve the structure’s dimensional stability.

Detection of discontinuities in materials and structures through methods such as magnetic-particles, ultrasound and x-rays, ensuring the integrity and quality of the components manufactured.

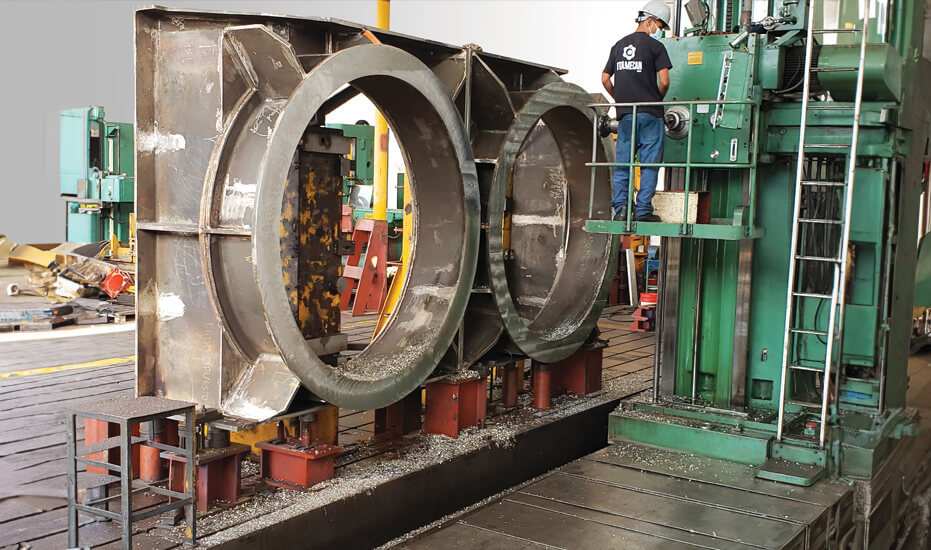

We offer a broad and complete machining capacity for any process, regardless of its complexity, as well as the possibility of carrying out large machining operations or machining of large parts.

We have staff specialized in structure assembly, guaranteeing the correct fit and alignment of the parts to ensure maximum accuracy and stability.

Provision of the necessary documents, including quality certificates, test reports and traceability record to ensure compliance of our manufactured structural components with the applicable regulations and standards.