Reliable power, unmatched performance at every turn

We specialize in the integral multi-brand maintenance of speed reducers and transmission boxes. We carry out an accurate fault diagnosis using our modern infrastructure and state of the art dimensional and metallographic control tools. Our complete infrastructure allows us to carry out all the necessary processes for comprehensive maintenance, to achieve traceability and strict controls in every stage of the process. We produce OEM quality spare parts based on reverse engineering for the main components of the most renown brands in the market, offering high quality and reliability maintenance services. Also, we provide a comprehensive post sales follow-up service to analyze any possible faults in the operation or selection of the equipment to increase operational reliability and reducing maintenance costs in every stage.

Our commitment is to ensure that each reducer operates optimally and durably, guaranteeing maximum customer satisfaction and efficiency in their operations.

EXPERTS IN THE LEADING BRANDS OF THE MARKET

Our comprehensive maintenance service is designed to ensure that your speed reducers run with maximum efficiency and reliability. We carry out predictive and corrective maintenance of reducers and gearboxes, adapted to the specific needs of each customer. With a quality and accuracy approach, we use advanced technology and a highly trained team of engineers to guarantee that each component works perfectly. Also, we provide OEM quality spare parts based on reverse engineering, which allows extending the life span of your equipment and reduce downtime.

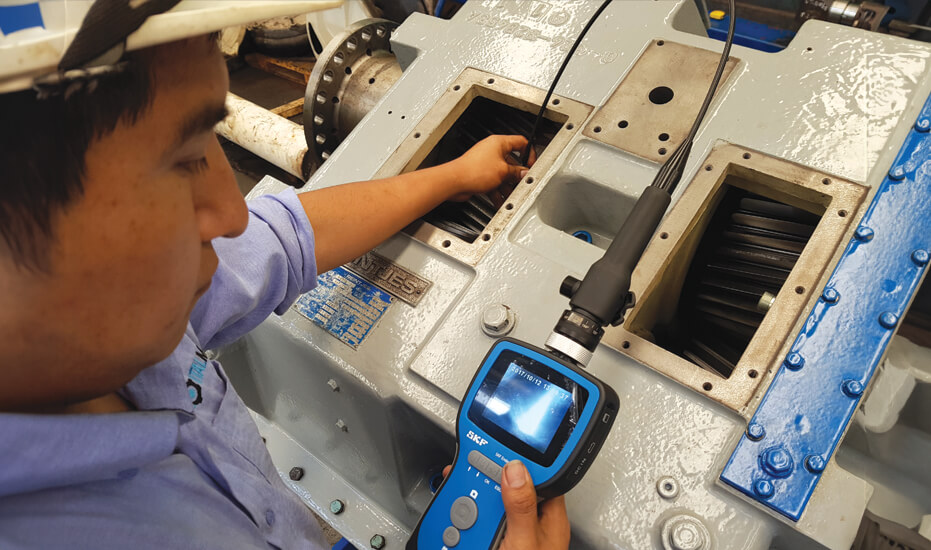

Our field inspection and condition monitoring are focused on early detection of possible faults, and predictive maintenance of your equipment. We carry out regular visits to your facilities to inspect and assess the condition of your reducers and other critical components.

Our field installation service guarantees that the implementation of your equipment is carried out in an efficient and accurate manner. We have a specialized team that goes to your facilities to install the reducers, gearboxes, and other critical components. We follow strict procedures and quality and safety standards to ensure that each piece of equipment is correctly installed and ready to run at full capacity. All the same we offer training and technical support during the installation to ensure seamless transition and correct operation of the equipment from day one.

Our service agreements are designed to provide continuous and specialized technical support, ensuring that your equipment is maintained in optimal operating conditions. We offer customized plans that include scheduled maintenance, continuous monitoring and priority service for repairs and emergencies. By entering into a service agreement with us, you guarantee maximum equipment reliability and performance, minimizing downtime and optimizing productivity. We become your strategic partner in maintenance, allowing you to focus on your business while we take care of the operational health of your equipment.

We are specialized in gear manufacturing using state-of-the art software for the analysis and design of gear drives. Our advance approach allows creating lasting gears that meet the highest quality standards. Also, we apply reverse engineering techniques to analyze and produce existing gears and other reducer components, ensuring perfect adaptation and optimal functionality. With our expertise and technology, we guarantee efficient and customized solutions for any component replacement need of the main reducer and gear drive brands.

We offer optimization and updated reducer services for the main market brands to improve the performance and efficiency of your equipment. Our team of experts analyzes and assesses the current condition of your reducers, identifying opportunities to improve their operation and extend their useful life. Thanks to our deep knowledge of the main market brands, we can offer customized solutions that adapt perfectly to your specific needs, ensuring reliable and efficient operation.

Our commitment is to ensure that each gearbox operates optimally and durably, guaranteeing maximum customer satisfaction and efficiency in their operations.